The first Concours of Elegance, held in 2012, was conceived as a one-off event, as part of Her Majesty the Queen’s Diamond Jubilee. It was so well received that plans were quickly made for another event the following year, this time at a different Royal Palace, swapping Windsor Castle for St James Palace in central London. And you could say that after that event went down at least as well as the first, the die was cast for an annual event to be squeezed into the motoring calendar. Initially, the event moved to a different venue every year but when the location for the 2017 Concours was announced to be a return to Hampton Court, so it was also declared that this would be the home of the event right through to 2022, thereby committing this event to the calendar for at least five more years. With the exception of the 2015 event which was up in Edinburgh, I’ve attended every one and always enjoyed them very much, so although the 2018 event, like previous years, clashed with a lot of other tempting events going on at the same time, it was an easy decision to prioritise this one. The Concours takes place over three days, Friday to Sunday, and on this occasion, I attended on the Saturday. Here is what I saw.

THE 2018 CONCOURS

This is the core of the event, of course. A Steering Committee, comprised a number of well-known names across the industry, are responsible for drawing up a list of cars to attend, with criteria including the fact that they have not been shown at this event before and that they are in some way special and in most cases rare. As is often the case with older cars, despite the best of intentions, not everything goes quite to plan, so a look at the list of cars declared to be in the display and those that were actually on site do not quite correlate with a few that simply were not there and a couple that were present but which did not feature on the official list. I am pretty sure that the photographer did not miss any of the cars that were on site, so that does mean some text with no accompanying photo. In the best traditions of a Concours, there is a competitive element, with an award for Best in Show, decided by the owners of the cars. This year it went to the stunning Mercedes-Benz S Barker Boat-Tail.

1903 Panhard et Levassor O4R

This is a 1909 Isotta Fraschini Tipo A FENC. The Isotta Fraschini Tipo FE was an early Italian race car, and the Isotta Fraschini Tipo FENC is the road version and is considered one of the earliest examples of a sports car. Long rumoured to have been designed by Ettore Bugatti, the racing FE and road going FENC voiturettes were designed by pioneering Italian engineer Giuseppe Stefanini, with collaboration from chief design engineer Giustino Cattaneo. Drawing from his first race car design, the monstrous 17.2 L SOHC inline-four in the Isotta Fraschini Tipo D, which lasted but one lap in the 1905 Gran Premio di Brescia, Stefanini applied similar principles on a diminutive scale. In early 1908 he created the Tipo FE for entry in the Grand Prix des Voiturettes at Dieppe. The racing FE was the prototype for the production model, the FENC (FE Non Competizione). The FE, with its innovative 3000 rpm, 18 hp, 1.2 litre SOHC inline-four was designed to the minimum 600 kg (1323 lbs) weight limit for the 1908 Grand Prix de Voiturettes, and had a top speed of 95 km/h at an engine speed of 2500 rpm. It featured a 3-speed transmission with direct-drive top gear (not a 3-speed with overdrive as some early historians thought). While the three examples built were not particularly successful in their only competition at Dieppe on July 6, 1908 (8th, 14th, DNF), the FE heralded the death knell for the locomotive-like single- and twin-cylinder race cars of the day. The FE’s design became the Continental standard and the archetype for the small high performance sports car, although Isotta Fraschini themselves abandoned the concept almost immediately. None of the FEs are known to survive. Consistent with Isotta Fraschini’s policy of deriving road cars from its race cars, the prototype FE quickly led to a road-going FENC design in the latter half of 1908. A larger engine capacity of 1.32 litre rated at 14 hp at 2500 rpm, with a cross-drive water pump and magneto, and a four- rather than three-speed transmission (evidenced by driving any of the remaining FENCs) were the major changes. Four versions were offered in 1909: bare chassis, Tipo A (Dieppe racing type, no fenders, running boards, or lights), 6750 Lire (fenders, running boards, lights an additional 250 Lire) – this version $2750 US; Tipo B (touring type, cloth roof, fenders and lights), 6950 Lire; Tipo C (touring type, leather and cloth roof, fenders and lights), 7870 Lire. Top speed at 2500 rpm was 75 km/h with European wheels (710 mm) and 84 km/h with export wheels (810 mm). Due to the severe economic conditions following the Panic of 1907, and a fading of buyers’ interest in voiturettes, the FENC was produced for only about one year. Today only five Tipo FENCs are known to exist of less than 100 built.

This striking 95-year-old 1913 Renault Type DP Coupé Chauffeur is unique in its originality; every single body panel and piece of interior trim is as it was when it was built. Owned by the same family for its entire life, it’s an impeccable piece of history, featuring three types of lighting: gas for the headlights, electric for the interior and oil for the rear red lamp.

1912 Rolls-Royce Silver Ghost Torpedo Phaeton ‘Taj Mahal’

1914 Rolls-Royce Silver Ghost Torpedo Phaeton

1924 Alfa Romeo RL Targa Florio #2. In the early 1920s, the Italian automotive engineer, Giuseppe Merosi, designed the Alfa Romeo RL. This was not his first design for Alfa; his history with the company dates back to the early 1910s when he designed the A.L.F.A. 24 HP. During the mid-1910s he designed a DOHC four-cylinder engine that had 16-valves and displaced 4.5-litres. The Alfa Romeo RL was produced from 1922 through 1927. It had a displacement size of 2.9-litres from its six-cylinder engine, that would continue to increase in size throughout the years, culminating with a 3.6-litre size and around 125 bhp. There were four versions of the RL created, the Normale, Turismo, Sport, and RLTF (for Targa Florio). The RLTF was a purpose-built, racing versions that was stripped of non-essential items, given sleek designs, and weighed about half of the other versions. The engine was finely tuned and given seven main bearings and double carburettors. It was used in competition by such legendary drivers as Ugo Sivocci, Enzo Ferrari, Antonio Ascari, and Giulio Maset. The stage on which the Alfa Romeo RL achieved its greatest triumphs was the Targa Florio, where it secured a one-two finish in 1923 (in the two-seater spider configuration). Ugo Sivocci piloted the winning car and a third RL finished in fourth place. Sivocci’s car was the first painted with a green cloverleaf on a white background, which would later become the hallmark of Alfa Romeo competition cars and sportier production models. Numerous racing drivers enjoyed success after choosing the RL, from Giulio Masetti and Antonio Ascari to Giuseppe Campari and a young Enzo Ferrari. The 1923 edition of the Targa Florio served up a barnstorming finale. Alfa Romeo entered five RL models driven by: Antonio Ascari (the father of future Formula 1 World Champion Alberto), Giuseppe Campari, Giulio Masetti, Enzo Ferrari and Ugo Sivocci. On the fourth and final lap of the Madonie circuit, Ascari emerged first from the hills, but around two hundred metres from the finish line his car broke down and stopped on the Cerda station bend. With the help of mechanics, who climbed into the car with naive enthusiasm, Ascari managed to cross the finish line first, but the race commissioners ordered him to retrace his steps and finish the race without the extra passengers. In the meantime Sivocci, who had been in second place until that point, took over the lead and clinched the first of Alfa Romeo’s ten victories in the Targa Florio, as well as the first international triumph for the Milanese car maker.

The 1925 Bugatti Type 35 Grand Prix Two-Seater is often thought of as THE classic Bugatti. The Type 35 was phenomenally successful, winning over 1,000 races in its time. It took the Grand Prix World Championship in 1926 after winning 351 races and setting 47 records in the two prior years. At its height, Type 35s averaged 14 race wins per week. Bugatti won the Targa Florio for five consecutive years, from 1925 through 1929, with the Type 35. The original model, introduced at the Grand Prix of Lyon on August 3, 1924, used an evolution of the 3-valve 1991 cc overhead cam straight-8 engine first seen on the Type 29. Bore was 60 mm and stroke was 88 mm as on many previous Bugatti models. 96 examples were produced. This new powerplant featured five main bearings with an unusual ball bearing system. This allowed the engine to rev to 6000 rpm, and 90 hp was reliably produced. Solid axles with leaf springs were used front and rear, and drum brakes at back, operated by cables, were specified. Alloy wheels were a novelty, as was the hollow front axle for reduced unsprung weight. A second feature of the Type 35 that was to become a Bugatti trademark was passing the springs through the front axle rather than simply U-bolting them together as was done on their earlier cars. A less expensive version of the Type 35 appeared in May, 1925. The factory’s Type 35A name was ignored by the public, who nicknamed it “Tecla” after a famous maker of imitation jewellery. The Tecla’s engine used three plain bearings, smaller valves, and coil ignition like the Type 30. While this decreased maintenance requirements, it also reduced output. 139 of the Type 35As were sold. The Type 35C featured a Roots supercharger, despite Ettore Bugatti’s disdain for forced induction. Output was nearly 128 hp with a single Zenith carburettor. Type 35Cs won the French Grand Prix at Saint-Gaudens in 1928, and at Pau in 1930. Fifty examples left the factory. The final version of the Type 35 series was the Type 35B of 1927. Originally named Type 35TC, it shared the 2.3 litre engine of the Type 35T but added a large supercharger like the Type 35C. Output was 138 hp, and 45 examples were made. A British Racing Green Type 35B driven by William Grover-Williams won the 1929 French Grand Prix at Le Mans. The Type 35 chassis and body were reused on the Type 37 sports car. Fitted with a new 1496 cc straight-4 engine, 290 Type 37s were built. This engine was an SOHC 3-valve design and produced 60 hp The same engine went on to be used in the Type 40.

This 1929 Mercedes-Benz S Barker Tourer ‘Boat Tail’ was based on the 1927 Mercedes S-Type. Originally owned by racing enthusiast and British Racing Drivers’ Club co-founder Earl Howe, this ‘Boat Tail’ car was fitted with a revolutionary body which incorporated a lightweight and aerodynamic shell with unique aircraft-inspired aluminium side pods crafted by English coachbuilders Barker. Over the years, the majority of Earl Howe’s unique specifications were all but lost, until a recent sympathetic restoration brought it back to its former glory.

Also dating from 1929 is this Rolls-Royce Phantom I Brewster Riviera. All Rolls-Royces are special, but some are totally unique. This example may be one of ten Riviera Phantom I cars built, but it’s the only example specified by its owner with gold-plated exterior trim as far as the eye could see. Bought by Irene Schoelkopf Carman in 1929, it also comes fitted with a few of her other ‘optional extras’, including a Dunhill lighter, an intercom for communicating with the driver and a mirror pad.

1929 Rolls-Royce Phantom I Coupé Chauffeur

This 1931 Bugatti Type 54 belongs to American collector Peter Mullin, and it was on show at Prescott on at least a couple of occasions last year. Bugatti developed the Type 54 prototype in 1931 as an alternate approach to competition with Germany’s and Italy’s high-powered racecars. Whereas previous Bugatti racecars had focused on finesse, this model focused on power and it was created in something of a hurry. Rumour has it that the first two Bugatti Type 54s were put together in just 13 days, using Type 45 chassis frames and Type 50 motors, prior to the 1931 Italian Grand Prix at Monza. The Type 50 straight 8 engine has a capacity of 4.972cc and is fitted with twin carburetors and a supercharger to produce around 300hp, but this also made it the largest and heaviest of the Bugatti racecars, so much so that it proved difficult to handle. At times the vehicle’s weight and power caused the tyres to detach from the rims, resulting in a large number of crashes. Archille Varzi drove chassis #54201 to a third place finish in that 1931 Monza event and it was later sold to Czech Republic Prince Jiri Lobcowicz. The Prince was killed racing #54201 at Avus Germany in 1932 and the remains of #54201 were acquired by his friend and fellow competitor Zdenek Pohl. Zdenek had Prague coach builder O Uhlik fit the Roadster ‘Praha’ body seen here, to the repaired chassis #54201. In the 1970’s the ‘Praha’ body was removed from #54201 in favour of a body better suited to competition on the track. Skip Berg, a California car dealer, later still found the Uhlik ‘Praha’ roadster body, and had it fitted to a chassis built up by Uwe Hucke and given the chassis number BC-70 by the Bugatti Owners Club.

1932 Alfa Romeo 8C 2300 Short Chassis Spider

Dating from 1935 is this Tatra 77, a car considered to be the first serial-produced, truly aerodynamically-designed automobile. It was developed by Hans Ledwinka and Paul Jaray, the Zeppelin aerodynamic engineer. Launched in 1934, the Tatra 77 is a coach-built automobile, constructed on a platform chassis with a pressed box-section steel backbone rather than Tatra’s trademark tubular chassis, and is powered by a 60 bhp rear-mounted 2.97-litre air-cooled V8 engine, in later series increased to a 75 bhp 3.4-litre engine. It possessed advanced engineering features, such as overhead valves, hemispherical combustion chambers, a dry sump, fully independent suspension, rear swing axles and extensive use of lightweight magnesium alloy for the engine, transmission, suspension and body. The average drag coefficient of a 1:5 model of Tatra 77 was recorded as 0.2455. The later model T77a has a top speed of over 150 km/h (93 mph) due to its advanced aerodynamic design which delivers an exceptionally low drag coefficient of 0.212, although some sources claim that this is the coefficient of a 1:5 scale model, not of the car itself. The Tatra 77 was a hand-built car with a leather interior. Some cars had a glass partition between the front and rear seats. A sliding roof was available. An unusual feature on a few of the T77 models was a central position for the steering wheel in the dashboard. The front-seat passengers were seated on either side of the driver and the seats placed slightly rearwards as in the modern-day McLaren F1. All other T77’s had the steering wheel on the right-hand side as Czechoslovakia (like a number of other European countries) drove on the left before the Second World War.

Supremely elegant for sure is this 1936 Lancia Astura Bocca Cabriolet. The Astura is the pinnacle of pre-war Lancias, placing it at the summit of pre-war Italian automotive engineering and design. Its combination of luxury and engineering refinement made it an ideal platform for coachbuilders, particularly in its more sporting Corto, or short-wheelbase version. Introduced in November 1931 as a replacement for Lancia’s flagship Dilambda, the new model represented a generational shift. Where the older model featured a 3,960-cc engine moving 2,010 kilograms, the new car would retain the same length but would be lighter and more efficient – its new, reduced displacement engine nonetheless giving it a better power-to-weight ratio than the earlier car. Reflecting a new Italian nationalism, Lancia broke their precedent of assigning their cars the letters of the Greek alphabet and instead named the new model Astura, after an ancient island castle south of Rome. Although Lancia had pioneered monocoque construction in their 1922 Lambda, the Astura was destined for carrozzerie and was given a cross-braced box-section platform to allow wider design latitude. The model was initially offered in a single 125-inch wheelbase as the Tipo 230, but for the 3rd Series, two versions were offered. Nine hundred and eight were built as Lungo, with a wheelbase of 131 inches as the Tipo 233L, while 328 were constructed to Corto specification on a wheelbase of 122 inches as Tipo 233C. Notwithstanding its more conventional construction, like its predecessors the chassis had excellent torsional stiffness, which contributed to its feeling of solidity and refinement. The front suspension retained Lancia’s sliding-pillar independent suspension, while the live rear axle was controlled by friction dampers that could be adjusted to suit with dashboard-mounted controls. A Bijur central lubrication system was provided. The 3rd Series also received a Dewandre brake servo and a 78-litre fuel tank. An option for late cars was a hydraulic braking system, built by Marelli under license from Lockheed. As with the Dilambda that preceded it, the Astura was given a narrow-angle V-8 engine. Initially at 19-degrees with a displacement of 2,604 cc and producing 73 bhp at 4,000 rpm, by the introduction of the 3rd Series in 1933, it had grown to 2,972 cc at an angle of 17-degrees 30-minutes, in which form it produced 82 bhp at 4,000 rpm. The narrow-angle architecture made for a compact unit – narrower than a conventional V-8 and shorter than an inline – with a single cylinder head. The head itself was unusual in having a cast iron lower section and an aluminium upper section. In between is the camshaft driven by a triplex chain with tensioner. The engine also featured an Autokleen oil filter, a unit that rotated a cleaning cylinder every time the engine was started. Although the engine was inherently quite smooth, it was set into the chassis on four rubber isolators. Fitted with a factory berlina body, the 3rd Series Astura weighed 1,500 kilograms, while the bare coachbuilders’ platform came in at 960 kilograms. To ensure that the car delivered the performance its well-heeled buyers expected, Lancia recommended that coachbuilders limit bodywork weight to no more than 460 kilograms. Although not primarily a competition car, the 3rd Series Asturas did achieve some success in that realm. In 1934, a Castagna-bodied Astura was driven to 10th place in the Mille Miglia by Mario Nardilli and Carlo Pintacuda. Later that year the same pair won the Giro d’Italia, a six-day, 3,534-mile circuit around Italy, finishing the grueling event in 65 hours, 57 minutes, and 6 seconds at an average of 53.58 mph – a testament to the reliability and road-handling of the model. Further reinforcing the car’s capability, another Astura driven by Giuseppe Farina and E. Oneto finished third. The present car, Tipo 233C chassis number 33-5313, is one of 328 Corto versions produced on the short-wheelbase 122-inch platform. Fitted with engine number 91-1171, it was delivered as a bare chassis to Pinin Farina in the summer of 1936 and clothed in a body designed by Mario Revelli di Beaumont, who took full advantage of the narrow-angle V-8 to create a rakish yet restrained cabriolet design, dubbed the Tipo Bocca. It was commissioned a Lancia dealer in Biella who ultimately ordered a total of six Bocca cabriolets in both corto and lungo chassis. The aerodynamic profile features a sloping, rounded grille, whose horizontal bars are interrupted by a dramatic “waterfall” of chrome strakes running from the slim, elegant bumper to the base of a vee’d windshield. The peaked front fenders are separated from the body by rounded fairings that feature individually integrated headlights and driving lights, while the rear fender spats also contribute to the clean, smooth lines. The open car’s streamlined horizontal emphasis is reinforced by a chrome strake running the entire length of the body as well as horizontal engine compartment vents, features that are accentuated when the halves of the split windshield are folded flat. Gently curving body sides feature an early use of curved side windows. Highlighting the car’s restrained elegance was its subtle, pale grey paint with blue upholstery and power-actuated convertible top, the latter a great novelty for 1936. The newly completed cabriolet was displayed on the Pinin Farina stand at the 1936 Salone del l’Automobile, Milano, where it received the President’s Cup from the Registro Ancetre Club Italia. Following the show, chassis number 33-5313 was acquired by Ghiara & C., Lancia’s main agent in Genoa. Ghiara sold the car to Cav. Piero Sanguineti, a local industrialist, for about 75,000 Lire (the equivalent of about $4,200 at the time). In May 1937, Sanguineti showed the car in the inaugural Concorso d’Eleganza per Automobili, San Remo, where it received a class award. The car was subsequently purchased by Emil Uebel, Lancia’s German distributor, who apparently kept it in his main facility in Berlin-Charlottenburg. Wartime records no longer exist, offering no explanation of whether Uebel sold the car or retained it for himself, or how and where the car survived the conflict. But survive, it certainly did, and in early 1947 it was acquired by American collector Barney Pollard, as part of a package deal with two steam locomotives. Pollard shipped number 33-5313 to the United States and kept the car until 1980, when it was sold to Armand Giglio, former President of the American Lancia Club. Giglio held the car a further two decades, selling it in 2004 to an owner in Connecticut. Other than an older repaint, the car was in largely original condition, but with some deterioration of the body’s wood framing. The new owner undertook restoration of the wood framing, as well as some body preparation work. In this state the car was sold in late 2011 to Orin Smith, who commissioned Vantage Motorworks of Miami to complete the restoration to international concours standards. The finished car easily achieved Best in Class at the Classic Sports Sunday at Mar-a-Lago, and People’s Choice here at Amelia Island, both in 2013. The Lancia subsequently journeyed back to Italy, where it was judged Most Sympathetic Restoration at the 2014 Concorso d’Eleganza Villa d’Este, in the company of a thrilled Mr. and Mrs. Smith. More recently the car was exhibited at the Petersen Automotive Museum in Los Angeles, as part of their “Rolling Sculpture” exhibit of advanced streamlined design. Notably, a sister car to this lovely Astura, in long-wheelbase form was awarded Best of Show at the 2016 Pebble Beach Concours d’Elegance, cementing its importance to design and elegance for the era. This Lancia Astura ‘Corto’ cabriolet perfectly epitomizes Pinin Farina’s design of the pre-war period – restrained elegance with simple but precise details. As such, it represents an opportunity to acquire one of the most important and beautiful examples of Italian engineering and coachbuilding – a show car par excellence, now as then.

Oldest Aston Martin here was this 1937 Aston Martin 15/98 Long Chassis Tourer. Developed directly from the two Aston Martin ‘Speed Models’ destined for the 1936 Le Mans race and equipped with a 1974cc four-cylinder engine, the model we are presenting here has the same mechanical specification, but a longer chassis with room for two passengers in the rear. A very elegant but nonetheless sporting version, thanks to its engine producing 98bhp, from which it derives its name as the 15/98 Tourer. Just 24 cars were built, of which it is understood from the AMOC’s records that only 11 remain around the world.

1937 Alvis 4.3-Litre Vanden Plas Concealed Head Coupé

1938 Bentley 4 ¼ Litre Sports Cabriolet by Erdman & Rossi

1938 Lagonda V-12 Rapide Coupé. In the mid-1930s the Lagonda brand was given a new lease of life, under Technical Director W.O. Bentley, with the aim of creating the legendary V12. Most special of all the Lagonda V12s produced were these Rapide models, fitted with the short sports chassis and gorgeous art deco bodywork.

1949 Bentley Mk VI Lightweight Coupé

This 1949 Ferrari 166 Inter Superleggera is the oldest known Ferrari in the UK and it has quite a history having competed in the Mille Miglia four times. Now on its 6th owner, it is sued regularly and can be seen at a good number of events around the country during the year. The Ferrari 166 Inter was Ferrari’s first true grand tourer. An evolution of the 125 S and 166 S racing cars, it was a sports car for the street with coachbuilt bodies. The Inter name commemorated the victories claimed in 166 S models by Scuderia Inter. The 2.0 litre Gioacchino Colombo-designed V12 engine from the 166 S remained, as did its chassis, though the wheelbase would eventually grow from 2420 mm (95 in) to 2500 mm (98 in). Output was 110 to 140 hp at 6,000 rpm with one to three carburettors. The 166 Inter shared its Aurelio Lampredi-designed tube frame and double wishbone/live axle suspension and 2420 mm wheelbase with the 125 S and 166 S. The first Ferrari GT car debuted at the Paris Motor Show on October 6, 1949. It was an elegant coupe designed by Carrozzeria Touring of Milan who had previously created a number of similar Ferrari and Alfa Romeo models. Customer sales soon started, with 166 Inter models becoming the first Ferraris to be purchased for the road rather than the race track. As was typical at the time, a bare chassis was delivered to the coachbuilder of the customer’s choice. Many used Touring, but Ghia’s one-off Boano coupe was more daring. Others were built by Stabilimenti Farina, who penned a Cisitalia 202-like coupe. Vignale also joined in, presaging their designs of the coming decade, and two cabriolets created by Stabilimenti Farina and Bertone foreshadowed those companies’ later involvement with Ferrari. 37 166 Inters were built from 1948 through 1950 before the car was replaced by the 195 Inter and 212 Inter in 1950 and 1951.

There were two examples of the Aston Martin DB2, a 1950 Aston Martin DB2 DHC 1st Sanction and a later 1953 DB2/4 Coupe. This was the first new post-war Aston, and the first car to adopt the now legendary DB naming convention, reflecting the fact that in 1947 David Brown had bought the Aston Martin and Lagonda companies and incorporated them as Aston Martin Lagonda Ltd. Lagonda’s 2.6 litre dual overhead cam, straight-six engine, more powerful than the pushrod 1.9 litre unit in the Aston Martin 2-Litre Sports, was the main objective in Brown’s acquisition of the company. W. O. Bentley had supervised the engine’s design, which was largely by William (Willie) Watson, an engineer with the pre-war Invicta company who had collaborated on Lagonda’s pre-war V12 and also designed the short-lived post-war version. Work then started on producing a new car, which was called the DB2. This new model would utilise a version of the Lagonda engine in a shortened version of the tube-frame chassis designed by Claude Hill for the Aston Martin 2-Litre Sports, with a fastback coupé body designed by Frank Feeley. Three pre-production cars were entered for the 1949 24 Hours of Le Mans. One, which would become the development car for the production DB2, had the Lagonda straight-6, while the four-cylinder Aston Martin 2-litre unit powered the other two. After six laps the Lagonda-powered car, driven by Leslie Johnson, retired with overheating caused by failure of the water pump. One of the 2-litre cars was in 4th place and running without brakes when it crashed two hours short of the finish, fatally injuring driver Pierre Maréchal. The other finished 7th, crewed by Arthur Jones and Nick Haines. A month later, the larger-engined car, driven by Leslie Johnson and Charles Brackenbury, finished 3rd in the Spa 24-hour race, where one of the 2-litre cars was driven to 5th by Nick Haines and Lance Macklin. For 1950 all three factory team cars were equipped with the Lagonda engine. At the 1950 Le Mans race the one driven by George Abecassis and Lance Macklin finished 5th, with Brackenbury and Reg Parnell bringing another home 6th, which won Aston Martin 1st and 2nd in the 3-litre class. Across the Atlantic, Briggs Cunningham drove his DB2 to 2nd in its class at the inaugural Sebring race meeting in December 1950. The factory team cars continued racing in Europe throughout 1951, including at Le Mans, where Macklin and Eric Thompson took 3rd overall, with Abecassis and Brian Shawe-Taylor 5th. David Brown soon embarked on a series of Aston Martins designed specifically for competition use, starting with the DB3. Meanwhile, the production DB2 debuted at the New York Auto Show in April 1950 and continued in production until April 1953, by which time 411 had been made. The first 49 had a chrome-framed front grille in three separate parts, and large rectangular cooling vents in the front wings. Subsequent cars had a one-piece grille with horizontal chrome slats, and no side vents. The single-piece bonnet was hinged at the front. At the rear of the fixed-head coupé (FHC) a small top-hinged lid gave access to the spare wheel, and luggage space was behind the front seats, accessible only from inside the car. Later in 1950, a Drophead Coupé (DHC) variant was introduced. At least 102 were built. In April 1950, an engine with larger carburettors, inlet camshaft the same as the exhaust (for increased duration), and higher compression ratio pistons (8.16:1) was made available. Aston Martin’s first Vantage upgrade option offered 125 hp. Initially the higher compression ratio made the engine unsuitable for the British market, as the postwar austerity measures of the early 1950s restricted UK vehicles to 72 octane “Pool petrol”. The first DB2 Vantage, LML 50/21, was delivered to, and raced by, Briggs Cunningham in the United States.

A revised version of the DB2 was launched in 1953, called the DB2/4. It was available as a 2+2 hatchback, marketed as a Saloon, as a Drophead Coupé (DHC) and as a 2-seat Fixed Head Coupe. A small number of Bertone bodied spiders were commissioned by private buyers. A further update in 1957 created the Mark III, and this was produced until the launch of the DB4 in 1958.

Far from familiar is this one-off, the 1950 166/212 Export with a body by Fontana which is often referred to as the “Uovo”, Italian for “egg”, a not illogical choice of name given its shape. It started off life as a 166 Barchetta Touring and was engaged in the Tour of Sicily and then the Mille Miglia, where it crashed. Giannino Marzotto asked the designed Franco Reggani to design a new body which coachbuilder Fontana would then realise. In 1951, in its new guise, it entered the same two races but finished neither of them, but would go on to have more success winning the Coppa della Toscana and finishing second in Porto. It appeared many times in the 90s at events and then just disappeared before resurfacing a couple of years ago.

Looking quite similar to that early Ferrari is this 1952 Alfa Romeo 1900 ‘Pre-series’ Sprint Coupé. The 1900C was introduced in 1951 as the coupe version of the four-door Alfa Romeo 1900. The addition of the C in the name wasn’t for coupe as many assume, but for corto – the Italian word for short. Although the 1900 model series was the first with a unibody chassis, and the the first to be fitted with the new 1884cc DOHC inline-4, the then general manager of Alfa Romeo, Iginio Alessio, chose to develop the unibody chassis in such a way that the iconic Italian carrozzerie, or coachbuilders, could build custom bodies for it. He had become concerned with the difficulty posed by creating custom bodies for these newly engineered cars – and as a result of this decision the Alfa Romeo 1900 and 1900C were both bodied by some of the greatest names in Italian coachbuilding – including Zagato, Touring, Pinin Farina, Bertone, Boneschi, Boano, Colli, Stabilimenti Farina, Vignale, and of course, Ghia. Alfa Romeo gave official contracts to Touring to build the sporty 1900 Sprint coupé and to Pinin Farina to build an elegant four seat Cabriolet and Coupé. Carrozzeria Zagato built a small series of coupés with the unofficial designation of 1900 SSZ, designed for racing with an aerodynamic lightweight aluminium body and Zagato’s trademark double bubble roof. One-off specials were numerous, from the famous Bertone BAT series of aerodynamic studies, to an infamous sci-fi like Astral spider designed by Carrozzeria Boneschi for Rafael Trujillo the dictator of the Dominican Republic. There was a Barchetta or “Boat Car” made by Ghia-Aigle in Lugano Switzerland designed by Giovanni Michelotti at the request of a wealthy Italian who had two passions: the ‘Riva’ boats and a woman, his mistress, the car has no doors or windscreen wipers.

1952 Bentley R-Type DHC

1953 Austin-Healey 100 Special Test Car

1953 Pegaso Z-102 Spyder

1954 Aston Martin DB3S Sports Racing

There was an “Otto Vu” Fiat here again this year, this time a 1954 Fiat 8V with a Vignale body. The Fiat 8V (or “Otto Vu”) is a V8-engined sports car produced by the Italian car manufacturer Fiat from 1952 to 1954. The car was introduced at the 1952 Geneva Motor Show. The Fiat 8V got its name because at the time of its making, Fiat believed Ford had a copyright on “V8”. With 114 made, the 8V wasn’t a commercial success, but did well in racing. Apart from the differential the car did not share any parts with the other Fiats (but many parts were made by Siata and they used them for their cars). The 8V was developed by Dante Giacosa and the stylist Luigi Rapi. The engine was a V8 originally designed for a luxury sedan, but that project was stopped. The Fiat V8 had a 70 degree V configuration, displaced 1,996 cc and was fitted with two twin-choke Weber 36 DCF 3 carburettors. In its first iteration (type 104.000) the engine had a compression ratio of 8.5:1 and produced 104 bhp at 5,600 rpm, giving the car a top speed of 190 km/h (118 mph). Improved type 104.003 had different camshaft timing for 113 bhp at 6,000 rpm; finally type 104.006 with an 8.75:1 compression ratio, revised camshaft timing and fuel system put out 125 bhp at 6,600 rpm. The engine was connected to a four speed gearbox. The car had independent suspension all round and drum brakes on all four wheels. Top management were preoccupied with more run of the mill projects, however, and only 114 of the high-performance coupés had been produced by the time the cars were withdrawn from production in 1954. Nevertheless, they continued to win the Italian 2-litre GT championship every year until 1959. 34 of the cars had a factory produced bodywork by Fiat’s Reparto Carrozzerie Speciali (“Special Bodies Department”). Some cars had the bodywork done by other Italian coachbuilders. Carozzeria Zagato made 30 that they labelled “Elaborata Zagato”. Ghia and Vignale also made bodyworks. Most were coupés, but some cabriolets were made as well. An example fitted with a factory-style glass-fibre reinforced plastic body was displayed at the 1954 Turin Motor Show. The composite bodyshell—produced by Fiat’s experimental bodywork department—weighed just 48.5 kg (106.9 lb). This 8V currently resides in the Centro Storico Fiat in Turin.

Quite a rarity, this is a 1954 Frazer Nash Le Mans Coupé. The cars had a 2-litre 16-valve engine. The car pictured won its class at the 1952 Le Mans 24 Hours (13th overall) driven by Ken Wharton and Lawrence Mitchell. The next year it was placed 11th overall driven by Marcel Becquart and Maurice Gatsonides. Similar to the Frazer Nash Targo Florio, 9 Le Mans Coupés were built, three of which raced at le Mans.

This 1954 Jaguar XK120 is unique, in being the only one ever to be bodied by Pininfarina. In 1954 it went straight from the Jaguar factory in Coventry to Italy to have its beautiful bodywork applied, before being shown at the Geneva Motor Show in 1955. This car was very recently the subject of a 6750-hour nut-and-bolt restoration by Classic Motor Cars to bring it back to exactly how it left Pininfarina in the ‘50s.

There were two examples of the Bentley S1 Continental, a 1955 Drophead Coupé and a 1956 Bentley S1 Continental Coupe.

This 1957 Ferrari 500 TRC by Scaglietti was named after the FIA ‘C’ racing regulations to which it was built to comply. Many will claim that this 500 TRC, or ‘Testa Rossa C’, is one of the most beautiful Ferraris ever built. This particular example is the last TRC produced, and the last ever four-cylinder car Ferrari made. It also comes complete with an impressive race history, including class wins at both the 1957 12 Hours of Sebring and 24 Hours of Le Mans.

Dating from 1957 is this Fiat 1200 Vignale ’Wonderful’, one of a series of succesfully-executed Michelotti Fiat coupes that were built by Vignale in Grugliasco in the 1950s. before Vignale produced a number of models bearing his own name, such as the Vignale 850, 124 Eveline and 125 Samantha in the 1960s. Just 5 of the Wonderful were built. All benefitted from two-tone paintwork, which along with tasteful brightwork and whitewall tyres made the car look quite special. There were special matching interior tones, mated to a standard Fiat 1200 dashboard, instrumentation and steering wheel. The real innovation came from the removable roof panels, with a lift-out roof section of the type which would come to be known as a “targa top”, an idea which saw its next appearance on the Triumph TR4, also a Michelotti design. It was demonstrated to useful effect when a Paris-registered Wonderful appeared briefly in the 1966 French film “Les Combinards” (“the Racketeers”), a black and white movie directed by the audacious Jean-Claude Roy. This stylish car more than held its own in the display here in the company of cars wit much more exotic nameplates.

This 1958 Maserati 300S was driven by Stirling Moss when it was new. The Maserati 300S was a racing car produced between 1955 and 1958, which competed in the FIA’s World Sportscar Championship. Twenty-six examples were produced. The 3.0-litre (approx 245 bhp at 6200 rpm) engine was based on the Straight-6 design of the Maserati 250F and incorporated a lengthened stroke developed by Vittorio Bellentani to increase the capacity from the original 2.5-litres. The compression ratio was reduced from 12:1 to 9.5:1, partly due to the FIA regulations requiring the engine to be run on road car fuel. It used three Weber carburettors, initially 42DCO3, later 45DCO3. A trellis structure was used instead of the tubular one of the 250F, and the aluminium body was by Medardo Fantuzzi. The brakes were the same as the 250F, precisely machined alloy drums with extensive finning. The suspension was also of the same design as the 250F but with some strengthening to cope with the rougher tracks and road surfaces encountered in WSC racing. New features for the 300S included the incorporation of a De Dion type rear axle, a transverse four-speed gearbox and two chain driven camshafts. After a poor showing in the first season (1955) due mainly to mechanical malfunctions and development problems, it won at the Nürburgring in 1956 and finished second overall. It was second to the Maserati 450S, and was followed by the Maserati 350S. After the Guidizzolo accident (1957), the last few 300S were sold to customers in the USA. Giulio Alfieri gave up an attempt to fit it with fuel injection. One 300S was developed with the new V12 engine, becoming the Maserati 350S.

This 1960 Aston Martin DB4 GT Coupé was the first of a number of DB4 models I came across at the event.

A car I’d not heard of before was this 1961 Intermeccanica IMP 700GT. Intermeccanica was founded in Turin, Italy, in 1959. Its first project was speed equipment kits for Renault, Simca, Peugeot, and DKW. Kits consisted of dual throat carburettors, intake manifolds, high-performance cams and oil filters. A full line of free-flow exhaust systems was developed for 50 or more European cars in co-operation with an Italian tube company. These were marketed under the Intermeccanica label everywhere but North America, and sold particularly well in South Africa. In North America, they were distributed by Stebro, who eventually made the systems themselves. In 1960, from modifications of Peugeot engines a Formula Junior de-stroked, a counterweighted engine was developed, using the facilities of Conrero. A Formula Junior racing car, one of the first with a rear engine, was also built and sold. When the English Formula Juniors with Ford-based engines in the rear came out a few months later, the IM was outclassed. However, about ten engines were sold. A small aluminium two-seater coupe was developed by Intermeccanica, based on the Austrian Puch 500. The Puch was a hybrid, with part Fiat 500 chassis and body and part Puch mechanicals, namely a 500 cc air-cooled opposed twin engine, special brakes, and transmission. After a presentation of the prototype car to Steyr-Daimler-Puch AG in Graz, Austria, 21 of these small coupés were built. Some were touring cars, and some lightened for racing. The IMP won the 500 cc class one year at Nurburgring.

1962 AC Cobra Competition

This 1962 Ferrari 250 SWB Berlinetta was one of the most notable GT racers of its time, the 1959 250 GT Berlinetta SWB used a short (2,400 mm (94.5 in)) wheelbase for better handling. Of the 176 examples built, both steel and aluminium bodies were used in various road (“lusso”) and racing trims. Engine output ranged from 240 PS (237 bhp) to 280 PS (276 bhp). The “lusso” road car version was originally fitted with 185VR15 Pirelli Cinturato (CA67). Development of the 250 GT SWB Berlinetta was handled by Giotto Bizzarrini, Carlo Chiti, and young Mauro Forghieri, the same team that later produced the 250 GTO. Disc brakes were a first on a Ferrari GT, and the combination of low weight, high power, and well-sorted suspension made it competitive. It was unveiled at the Paris Motor Show in October and quickly began selling and racing. The SWB Berlinetta won Ferrari the GT class of the 1961 Constructor’s Championship. The car also won the 1960, 1961 and 1962 Tour de France Automobile before giving ground to the GTO’s.

This is a 1964 Porsche 904 GTS. Officially we should call this car the GTS, as Porsche had the same naming conflict with Peugeot over this as they did with the 911 (which they had originally planned to call 901, of course), but the reality is that everyone knows this elegant machine as the 904GTS. Although on the rare occasions that you see one, it tends to look like a road car, the 904GTS owes its existence to the race track. After having withdrawn from Formula One at the end of the 1962 season, Porsche focused again on sportscar racing. The 904 debuted late in 1963, for the 1964 racing season, as a successor to the 718, which had been introduced in 1957. Porsche designed the GTS variant to compete in the FIA-GT class at various international racing events. The street-legal version, as seen here, debuted in 1964 in order to comply with Group 3 Appendix J homologation regulations requiring a certain number of road-going variants be sold by the factory. Porsche produced 106 904s at four or five a day with a list price of US$7245. Orders far exceeded the one hundred car requirement to satisfy homologation rules and more cars could readily have been sold. The 904’s mid-engine layout was inherited from the 718 RSK. It was powered by the 1,966 cc Type 587/3,] four-cam flat four-cylinder engine producing 198 hp, “probably the most complex four-cylinder” ever. It drove a five-speed transmission. Begun as the Type 547, its development began in 1953, when the previous VW-based 1,100 cc flat-four, used in the contemporary 356 hit the limit of its potential. Porsche realised it needed something all-new. The brainchild of Dr. Ernst Fuhrmann, later Technical Director, it was hoped to achieve an “unheard of” 70 hp per litre, relying on hemispherical combustion chambers and two-choke Weber carburettors to generate 112 hp from the 1,500 cc four-cam engine. The 1.5 litre weighed 310 lb dry, eventually producing 180 hp. A complex design that proved “very taxing” to build and assemble, but very durable, it was used in 34 different models, including 550 Spyders, 356 Carreras, and F2/1s. The 904 was the first Porsche to use a ladder chassis and fibreglass body, appearing more like specialist racing cars than the modified sports cars typical at the time, and was painted white. The fibreglass body was bonded to its steel chassis for extra rigidity, and achieved a drag coefficient of 0.34. While many German race cars had used unpainted aluminium bodies since the famous 1934 Silver Arrows, most 904s were painted silver, the modern German national racing colour. Unusually for Porsche, the two-seater bodies were provided by contractors, which would later become standard practice among race car builders. The 904’s fibreglass body was made by spraying chopped fibreglass into a mould, the amount sprayed often varied in thickness over the shape of the car and as a result the weight of the various cars was somewhat inconsistent; some were heavier than others. Race-prepared four-cylinder 904s weighed in at approximately 1,443 pounds (655 kg) and the low weight gave the 904 the ability to accelerate to 60 mph from a standstill in less than six seconds (using the standard rear gear, which would be typical at Sebring) and to reach a top speed of 160 mph. Frontal area was only 14 sq ft. The Porsche 904 rode on coil springs (the first Porsche not to use trailing arm front and swing-axle rear suspension. To satisfy demand, twenty 1965 models were produced, some featuring a variant of the 911’s flat six,. These were known as the 904/6. Porsche also built a few factory race cars with a flat eight-cylinder power plant derived from the 1962 804 F1 car, the 225 hp 1,962 cc Type 771, but these had a “disturbing habit” of making their flywheels explode. These cars were known as the 904/8. A number of modern replica versions have been produced.

Dating from 1965 was this Aston Martin DB5 Convertible. 123 convertible DB5s were produced (also with bodies by Touring), though they did not use the typical “Volante” name until 1965. The convertible model was offered from 1963 through to 1965. Originally only 19 of the 123 DB5 Convertibles made were left-hand drive. 12 cars were originally fitted with a factory Vantage engine, and at least one further convertible was subsequently factory fitted with a DB6 specification Vantage engine. A rare factory option (actually fitted by Works Service prior to customer delivery) was a steel removable hard top. From October 1965 to October 1966, Aston Martin used the last 37 of the Aston Martin DB5 chassis’ to make another convertible model. These 37 cars were known as “Short Chassis” Volantes and were the first Aston Martins to hold the “Volante” name. Although calling it a “Short Chassis” is a bit of a misnomer as the “short” comes from comparing it to the subsequent DB6, which has a longer chassis. When compared to the DB5, it is not “short” but rather the same size, however these cars differ to the DB5 convertible models as they feature DB6 split front and rear bumpers and rear TR4 lights, as also used on the DB6.

There were two examples of the Ferrari 275 GTB here, a 1965 Alloy Long Nose and a 1965 275 6C Short Nose Berlinetta.

This 1967 Bizzarrini GT Strada 5300 is an example of the sports car produced by Bizzarrini from 1964 to 1968. Sold as an exceptionally low slung 2-seat coupe, roadster, and track-tuned “Corsa” racer, it proved to be Bizzarrini’s most successful model. Designed by ex-Ferrari chief engineer Giotto Bizzarrini in 1963, the Strada was launched by his company in 1964. It was similar in concept to the Iso Grifo, also designed by Bizzarrini, and even used the Grifo name while in the planning stage, as well as the welded unibody platform of the Iso Rivolta 300. The Strada – which adopted a Front mid-engine, rear-wheel-drive layout – was powered by a 327 Chevrolet small-block engine displacing 5,358 cc and rated at 365 hp to 385 Nm (284 lb⋅ft) of torque in the road legal version and 400 hp in the Corsa. The car could accelerate 0–100 km/h (62 mph) in less than 7 seconds, and attained a top speed of 280 km/h (174 mph). In later models, the 5,358 cc engine was replaced by a larger 7,000 cc unit, fitted with a Holley carburettor. Dunlop four-wheel disc brakes, a BorgWarner T-10 four-speed manual transmission, de Dion tube rear suspension, and limited slip differential were also used. The Giorgetto Giugiaro influenced Bertone styled aluminium body, was striking in its day and still regarded in the 21st century as “gorgeous” and an “absolute masterpiece”. Three spyder versions were also built, including a prototype which was a full convertible and two production versions which featured removable T-tops. In 1965, a Bizzarrini Grifo won its class at Le Mans and finished ninth overall. A total of 133 examples were produced from 1964 through 1968.

The 365 California replaced the 500 Superfast for 1966. It was the first 365 model, with its 4390 cc V12 based on the 330’s 4.0 litre Colombo unit but with an 81 mm bore. This later version of the Colombo engine was rated at 320 horsepower, in street tune using three Weber carburettors. The 365 California used the same chassis as the 500 Superfast but with an evolutionary cabriolet body by Pininfarina. Debuting at the Geneva Motor Show in 1966, just 14 examples were produced (including 2 in right hand drive) before production ended in 1967. Whilst the prototype was built on a 330 GT 2+2 type 571 chassis, production cars featured type 598 chassis. Chassis’ were sent to Pininfarina’s Grugliasco plant to be bodied and trimmed which were later returned to Ferrari for fitment of the mechanical components. It was presented at the 1966 Geneva Salon. Just 14 cars were built.

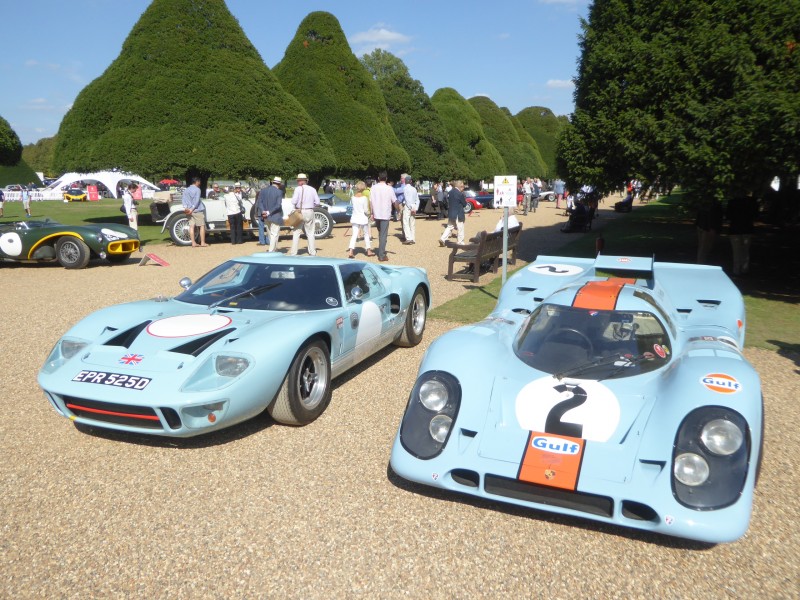

Dating from 1968 is this Ford GT40 Mk I Gulf #GT40P/1084. which competed in the Competition Sports Cars category with a 4.7-litre engine during 1968. This very car was raced by Paul Hawkins and David Hobbs to fourth place at the Spa 1000km race in May of that year.

This 1968 Jaguar XJ6 Series I is a well-known car, which was used by marque founder Sir William Lyons for a number of years.

Another competition car, this 1969 Porsche 917K #013(034) was driven by Steve McQueen in the classic film Le Mans. But this car was more than just a silver screen star, it was a genuinely successful racer on-track. Despite being damaged during filming for Le Mans, it was rebuilt using another chassis and went on to win at Daytona, Monza, the Osterreichring, Spa and Monthlery in 1971.

There was a 1970 Ferrari Dino 246 GT Coupé here, and I would come across another one elsewhere in the event.

This is a 1971 Lamborghini Miura P400 S. Some will say was the first true supercar. For sure, this car, produced between 1966 and 1973, is widely considered to have instigated the trend of high performance, two-seater, mid-engined sports cars. When released, it was the fastest production road car available. The Miura was originally conceived by Lamborghini’s engineering team, Gian Paolo Dallara, Paolo Stanzani, and Bob Wallace who in 1965 put their own time into developing a prototype car known as the P400. The engineers envisioned a road car with racing pedigree – one which could win on the track and be driven on the road by enthusiasts. The three men worked on its design at night, hoping to convince Lamborghini such a vehicle would neither be too expensive nor distract from the company’s focus. When finally brought aboard, Lamborghini gave his engineers a free hand in the belief the P400 was a potentially valuable marketing tool, if nothing more. The car featured a transversely-mounted mid-engine layout, a departure from previous Lamborghini cars. The V12 was also unusual in that it was effectively merged with the transmission and differential, reflecting a lack of space in the tightly-wrapped design. The rolling chassis was displayed at the Turin Salon in 1965. Impressed showgoers placed orders for the car despite the lack of a body to go over the chassis. Bertone was placed in charge of styling the prototype, which was finished just days before its debut at the 1966 Geneva motor show. Curiously, none of the engineers had found time to check if the engine would fit inside its compartment. Committed to showing the car, they decided to fill the engine bay with ballast and keep the car locked throughout the show, as they had three years earlier for the début of the 350GTV. Sales head Sgarzi was forced to turn away members of the motoring press who wanted to see the P400’s power plant. Despite this setback, the car was the highlight of the show, immediately boosting stylist Marcello Gandini’s reputation. The favourable reaction at Geneva meant the P400 was to go into production by the following year. The name “Miura”, a famous type of fighting bull, was chosen, and featured in the company’s newly created badge. The car gained the worldwide attention of automotive enthusiasts when it was chosen for the opening sequence of the original 1969 version of The Italian Job. In press interviews of the time company founder Ferruccio Lamborghini was reticent about his precise birth date, but stressed that he was born under the star sign Taurus the bull. Early Miuras, known as P400s (for Posteriore 4 litri), were powered by a version of the 3.9 litre Lamborghini V12 engine used in the 400GT at the time, only mounted transversely and producing 350 hp. Exactly 275 P400 were produced between 1966 and 1969 – a success for Lamborghini despite its then-steep price. Taking a cue from the Mini, Lamborghini formed the engine and gearbox in one casting. Its shared lubrication continued until the last 96 SVs, when the case was split to allow the correct oils to be used for each element. An unconfirmed claim holds the first 125 Miuras were built of 0.9 mm steel and are therefore lighter than later cars. All cars had steel frames and doors, with aluminium front and rear skinned body sections. When leaving the factory they were originally fitted with Pirelli Cinturato 205VR15 tyres (CN72). The P400S Miura, also known as the Miura S, made its introduction at the Turin Motorshow in November 1968, where the original chassis had been introduced three years earlier. It was slightly revised from the P400, with the addition of power windows, bright chrome trim around external windows and headlights, new overhead inline console with new rocker switches, engine intake manifolds made 2 mm larger, different camshaft profiles, and notched trunk end panels (allowing for slightly more luggage space). Engine changes were reportedly good for an additional 20 hp. Other revisions were limited to creature comforts, such as a locking glovebox lid, a reversed position of the cigarette lighter and windshield wiper switch, and single release handles for front and rear body sections. Other interior improvements included the addition of power windows and optional air conditioning, available for US$800. About 338 P400S Miura were produced between December 1968 and March 1971. One S #4407 was owned by Frank Sinatra. Miles Davis also owned one, which he crashed in October 1972 under the influence of cocaine, breaking both ankles. The last and most famous Miura, the P400SV or Miura SV featured different cam timing and altered carburettors. These gave the engine an additional 15 hp to a total of 380 hp. The last 96 SV engines had a split sump. The gearbox now had its lubrication system separate from the engine, which allowed the use of the appropriate types of oil for the gearbox and the engine. This also alleviated concerns that metal shavings from the gearbox could travel into the engine with disastrous and expensive results and made the application of an optional LSD far easier. The SV can be distinguished from its predecessors from its lack of “eyelashes” around the headlamps, wider rear wings to accommodate the new 9-inch-wide rear wheels and Pirelli Cinturato tyres, and different taillights. 150 SVs were produced.

This is one of six prototype 1983 Ferrari 288 GTO models that were built a year before production started. It is believed that just 3 of them remain.

This 1989 Aston Martin V8 Vantage Volante is known as the “Prince of Wales” spec. When Aston Martin unveiled the bespoilered Vantage Volante, the skirts and body enhancements were not quite to everybody’s liking. One particular customer, HRH, The Prince of Wales, who has owned a DB6 Mark II Volante since 1969, obviously wasn’t keen on the new additions. When the late Emir of Bahrain offered to purchase the Prince, as a gift, a brand new V8 Volante, Prince Charles requested Vantage performance yet with a more restrained look. Whilst the wheel aches were slightly flared and the larger 16 inch wheels and tyres of the V8 Vantage saloon were fitted, the resulting ‘Q car’ looked almost indistinguishable from a first series V8 Volante. Once Prince Charles had taken delivery of his rather special car, other customers began to ask for something similar. Thus AML began offering to those special people the new derivative which has become known as the V8 Vantage Volante Prince of Wales or PoW for short. Each subsequent car had their own unique features and thus no two are alike. Needless to say that the PoW is now considered as the pinnacle of the V8 range.

Dating from 1992 is this Jaguar XJ 220. As is well known, the XJ220 was developed from a V12-engined 4-wheel drive concept car designed by an informal group of Jaguar employees working in their spare time. The group wished to create a modern version of the successful Jaguar 24 Hours of Le Mans racing cars of the 1950s and ’60s that could be entered into FIA Group B competitions. The XJ220 made use of engineering work undertaken for Jaguar’s then current racing car family. The initial XJ220 concept car was unveiled to the public at the 1988 British International Motor Show. Its positive reception prompted Jaguar to put the car into production; some 1500 deposits of £50,000 each were taken, and deliveries were planned for 1992. Engineering requirements resulted in significant changes to the specification of the XJ220, most notably replacement of the Jaguar V12 engine by a turbocharged V6 engine. The changes to the specification and a collapse in the price of collectible cars brought about by the early 1990s recession resulted in many buyers choosing not to exercise their purchase options. A total of just 271 cars were produced by the time production ended, each with a retail price of £470,000 in 1992. The production XJ220 used a 3.5-litre twin turbocharged engine, which was given the designation Jaguar/TWR JV6. This engine, which replaced the Jaguar V12 engine featured in the concept car, was a heavily redesigned and significantly altered version of the Austin Rover V64V V6 engine. The decision to change the engine was based on engine weight and dimensions, as well as to environmental emission considerations. Use of the shorter V6 engine design allowed the wheelbase of the XJ220 to be shortened and its weight to be reduced; the V12 engine was definitively ruled out when it was determined it would have difficulty in meeting emissions legislation whilst producing the required power and torque. TWR purchased the rights to the V64V engine from Austin Rover in 1989 and developed a completely new turbocharged engine, codenamed JV6, under the auspices of Allan Scott, with proportions roughly similar to the V64V, and suitable for Sportcar racing. TWR redesigned all parts of the engine, increasing the displacement to 3.5 litres, and adding two Garrett TO3 turbochargers. The JV6 engine would first be used in the JaguarSport XJR-10 and XJR-11 racing cars; its compact dimensions and low weight made it an ideal candidate for the XJ220. The engine had a 90° bank angle, four valves per cylinder and belt-driven double overhead camshafts. It shares a number of design features with the Cosworth DFV Formula One engine. The V64V engine chosen had a short but successful career as a purpose-designed racing car engine. It was designed by Cosworth engine designer David Wood for Austin Rover Group’s Metro derived Group B rally car, the MG Metro 6R4. The redesign work necessary to create the Jaguar/TWR JV6 engine was undertaken by Andrew Barnes, TWR’s Powertrain Manager, and also involved Swiss engine builder Max Heidegger who had designed and built the race engines used in the XJR-10 and XJR-11 racing cars. The XJ220’s engine had a bore and stroke of 94 mm × 84 mm, dry sump lubrication, Zytek multi point fuel injection with dual injectors and Zytek electronic engine management. The engine was manufactured with an aluminium cylinder block, aluminium cylinder heads with steel connecting rods and crankshaft, and in the standard state of tune, it produced a maximum power of 550 PS at 7200 rpm and torque of 475 lb·ft at 4500 rpm. The XJ220 can accelerate from 0–60 miles per hour in 3.6 seconds and reach a top speed of 213 miles per hour.The exhaust system had two catalytic converters, which reduced the power output of the engine. During testing at the Nardò Ring in Italy the XJ220, driven by 1990 Le Mans Winner Martin Brundle achieved a top speed of 217.1 miles per hour when the catalytic converters were disconnected and the rev limiter was increased to 7,900rpm; owing to the circular nature of the track, a speed of 217 mph is equivalent to 223 mph on a straight, level road. The V64V engine had the additional benefit of being very economical for such a powerful petrol engine, it was capable of achieving 32 mpg, in contrast, the smallest-engined Jaguar saloon of the time, the Jaguar XJ6 4.0 could only achieve around 24 mpg. Four-wheel drive was decided against early in the development process, for a number of reasons. It was thought rear-wheel drive would be adequate in the majority of situations, that the additional complexity of the four-wheel drive system would hinder the development process and potentially be problematic for the customer. FF Developments were contracted to provide the gearbox/transaxle assembly, modifying their four-wheel drive transaxle assembly from the XJ220 concept into a pure rear-wheel drive design for the production car. A five-speed gearbox is fitted; a six-speed gearbox was considered but deemed unnecessary, as the torque characteristics of the engine made a sixth gear redundant. The transaxle featured a viscous coupling limited slip differential to improve traction. The transmission system featured triple-cone synchromeshing on first and second gears to handle rapid starts, whilst remaining relatively easy for the driver to engage and providing positive feel. The exterior retained the aluminium body panels of the XJ220 concept, but for the production vehicles, Abbey Panels of Coventry were contracted to provide the exterior panels. The scissor doors were dropped for the production model, and significant redesign work was carried out on the design when the wheelbase and overall length of the car was altered. Geoff Lawson, Design Director at Jaguar took a greater interest in the car and insisted the design had to be seen to be a Jaguar if it was to be successful in promoting the company. Keith Helfet returned to undertake the necessary redesign work mandated by the change in the wheelbase, which was reduced by 200 mm. The turbocharged engine required larger air intakes to feed the two intercoolers. Situated between the doors and the rear wheels, the air intakes were larger on the production version of the XJ220 than on the concept car. A number of small design changes for the body were tested in the wind tunnel; the final version had a drag coefficient of 0.36 with downforce of 3,000 lb at 200 mph. The XJ220 was one of the first production cars to intentionally use underbody airflow and the venturi effect to generate downforce. The rear lights used on the production XJ220 were taken from the Rover 200. The production model utilised the same Alcan bonded honeycomb aluminium structure vehicle technology (ASVT) as the concept car for the chassis. The chassis design featured two box section rails which acted as the suspension mounting points and would provide an energy absorbing structure in the event of a frontal impact, these were successfully tested at speeds up to 30 mph, an integral roll cage formed part of the chassis and monocoque, providing additional structural rigidity for the car and allowing the XJ220 to easily pass stringent crash testing.The rear-wheel steering was dropped from the production car to save weight and reduce complexity, as was the height adjustable suspension and active aerodynamic technology. The suspension fitted to the production model consisted of front and rear independent suspension, double unequal length wishbones, inboard coil springs and anti-roll bars, with Bilstein gas-filled dampers. The suspension was designed in accordance with the FIA Group C specifications. The braking system was designed by AP Racing and featured ventilated and cross-drilled discs of 13 in diameter at the front and 11.8 in diameter at the rear. The calipers are four pot aluminium units. JaguarSport designed the handbrake, which are separate calipers acting on the rear brake discs. Feedback from enthusiasts and racing drivers resulted in the decision to drop the anti-lock braking system from the production car. The braking system was installed without a servo, but a number of owners found the brakes to be difficult to judge when cold and subsequently requested a servo to be fitted. Rack and pinion steering was fitted, with 2.5 turns lock to lock; no power assistance was fitted. The Bridgestone Expedia S.01 asymmetric uni-directional tyres were specially developed for the XJ220 and had to be rateable to a top speed in excess of 220 mph, carry a doubling of load with the exceptionally high downforce at speed and maintain a compliant and comfortable ride. Rally alloy wheel specialists Speedline Corse designed the alloy wheels, these are both wider and have a larger diameter on the rear wheels; 17 inches wheels are fitted to the front and 18 inches are fitted at the rear, with 255/55 ZR17 tyres at the front and 345/35 ZR18 tyres at the rear. The interior was designed for two passengers and trimmed in leather. Leather trimmed sports seats are fitted together with electric windows and electrically adjustable heated mirrors. The dashboard unusually curves round and carries onto the drivers door, with a secondary instrument binnacle containing four analogue gauges, including a clock and voltmeter fitted on the front of the drivers door. Air conditioning and green tinted glazing was also fitted.The luggage space consists of a small boot directly behind and above the rear portion of the engine, also trimmed in leather. The car was assembled in a purpose-built factory at Wykham Mill, Bloxham near Banbury. HRH The Princess of Wales officially opened the factory and unveiled the first production XJ220 in October 1991. The JV6 engines used in the Jaguar racing cars were produced by Swiss engineer Max Heidegger, but delivering the number of engines required for the XJ220 program was considered beyond his capacity. TWR formed a division, TWR Road Engines, to manage the design, development, construction and testing of the engines for the production cars. The JV6 engine used in the XJ220 featured little commonality with the engines Heidegger built for use in the XJR racing cars, being specifically engineered to meet performance and in particular, the European emissions requirements, which the race engines didn’t have to meet. FF Developments, in addition to their design work on the gearbox and rear axle assembly were given responsibility for their manufacture. The aluminium chassis components and body panels were manufactured and assembled at Abbey Panels factory in Coventry, before the body in white was delivered to the assembly plant at Bloxham. The car, including chassis and body components, consists of approximately 3000 unique parts. The first customer delivery occurred in June 1992, and production rates averaged one car per day. The last XJ220 rolled off the production line in April 1994; the factory was then transferred to Aston Martin and used for the assembly of the Aston Martin DB7 until 2004. The regular Jaguar XJ220 is both rare and special enough, but for those who wanted something that bit more exclusive, Jaguar made a more potent version, the XJ220S. Just six were made. Think of it as a sort of XJ220 GT3 RS. Built to homologate the XJ220C GT racecar, it’s Jaguar’s supercar with extra power and added lightness. Tom Walkinshaw Racing who played a big part in XJ220 development, helped bring the S to life, stripping its weight by almost 400kg to 1080kg (thanks to all the aluminium bodywork being replaced by carbonfibre) and making it look meaner with a new front splitter, rear wing and more snarling side sills. The twin-turbo 3.5-litre V6 engine also had its output boosted from 542 to 680bhp. Enough to take its power-to-weight ratio way past a Bugatti Veyron’s. It is also somewhat louder than the standard car.

1997 McLaren F1 GTR Long Tail

This 1998 Mercedes Benz CLK GTR LM was based on the CLK GTR, which won the FIA GT Championship in both 1997 and 1998, but with a few choice revisions. Fitted with a V8 thought to be more suited to prolonged speeds than the GTR’s V12 to, as well as a new aerodynamic package, it was honed specifically for 24 hours of racing at Le Mans. However, despite the two cars qualifying in 1st and 3rd during the 1997 Le Mans 24 Hours, both retired with engine failure.

Newest car in the display was this 2018 Ferrari GTC4 Lusso from the ‘Tailor Made’ program, Finished in a bespoke Arancia paint, this car was customised to exactly the owner’s specifications. Released earlier this year as the replacement for the Ferrari FF, the car features a 6.3-litre V12 engine, capable of reaching speeds in excess of 200mph.

CAR CLUB and DEALER DISPLAYS

Whilst the Concours cars extend in two lines away from the Palace, the gravel pathways that go right up to the buildings provide space for plenty more cars to be displayed. To the left of the entrance is a length largely reserved for the selected Car Club of the day, and on the Saturday that was Jaguar, Friday having been the day for Aston Martin and Sunday would be for Bentley, though there were several examples of cars from both of those marques here. also to the right of the entrance were some very exclusive cars grouped together as the “Classics of the Future” as well as a number of individual and rather special cars parked up on the gravel paths. Add in the displays on the lawns from a mixture of dealers and manufacturers and there was ample to see here even without the Concours cars, with a mix of the familiar and the decidedly unusual.

ASTON MARTIN

In addition to the long line of Club cars present on the day I attended, there was a special Aston Martin feature running throughout the whole three days, celebrating 60 years of the Aston Martin DB4. The DB4 was the first in the Aston Martin trilogy that included DB5 and DB6, a series of three magnificent cars that secured the brand’s position in the hall of automotive fame. Handcrafted at Aston Martin’s, Newport Pagnell facility, DB4 was the brand’s first true Grand Tourer. It was an entirely new car with the platform chassis, disc brakes and 3.7-litre straight six-cylinder engine developed especially for the DB4, quite an achievement for a highly regarded but small British manufacturer. The evolution of the DB4 was gradual but constant with each ‘Series’ categorising individual changes to design or engineering performance. In 1959, the DB4 GT was introduced following on from its DB4 GT prototype forefather, DP199, that was raced by Sir Stirling Moss at Silverstone winning its first ever outing at the BRDC race in 1959. With bodywork made of thinner aluminium, the wheelbase reduced by 13cm, the engine tuned and the rear seats removed on all but a few examples, the DB4 GT enjoyed a long and distinguished career on the racing circuit.

The DB4 GT Zagato is regarded by many as one of the most beautiful cars of all time. Each DB4 GT rolling chassis was sent over to the Zagato factory in Milan where it received a lightweight body designed by Ercole Spada, creating the distinctive design. Raced at Le Mans, the factory only ever planned to produce 25 with only 19 cars completed. Due to its relative scarcity, the DB4 Zagato is considered one of the most desirable Aston Martins ever built.

The highest number DB4GT chassis (DB4GT/0201/L) was dispatched to the famous Italian coachbuilder, Bertone shortly before Christmas, 1960. And within a few short weeks, a fabulous notchback coupe body, reminiscent of Bertone bodied Ferraris of the time was added. At that time, the car, finished in light green with contrasting grey interior, was exhibited at the 1961 Geneva Salon. The ‘Jet’ as it was known was principally the work of Giorgetto Giugiaro was also shown at the Turin show in the same year. Unusually for an Aston Martin, the Jet has a body not of aluminium, but of steel which actually makes the car slightly heavier than the standard DB4GT. You may wish to contrast this car with the only other Aston Martin designed by Giugiaro, the twenty-twenty, unveiled at the 2001 Geneva Salon, exactly forty years after the Jet. And of course, Bertone produced the V12 Vanquish based Jet2 in 2004 and Rapide based Jet 2+2 in 2013. After a life on the exhibition circuit, the car spent time in the USA and then perhaps also Beirut of all places. After being unseen for sometime, it finally arrived at AML Works Service in 1986 where it has rebuilt to the highest standards. Not surprisingly, it has subsequently won awards at concourse events worldwide.

Complementing these splendid DB4s, and parked opposite them, was a line of the very latest Aston Martin models. These included the new Vantage, a DB11 Volante and the recently released DBS Superleggera.

Elsewhere there were plenty more examples of this much loved marque to admire.